Basic Info.

Model NO.

RC-RS

Main Application

Nature Gas, Common Steady-State Gases (Unstable Medium)

Size

Inserted Type: DN65-4000mm Pipeline: DN15-2000mm

Sensor

Flanged & Inserted Types

Application

Industrial Production

Type

Thermal Gas Mass Flow Meter

Measuring Media

Gas

Measuring Principle

Thermodynamic

Measurement Object

Closed Pipeline

Certification

CE, ISO

Measurement Range

0.5-100nm/S(20ºC, 101.33kpa)

Pipe Diameter Range

15mm~6000mm

Application Range

Suitable for All Kinds Mixed Gases. Various Corros

Medium Temperature Range

-40ºC-100ºC;-40ºC-200ºC

Sensor Diameter

Phi 3, Phi 2.5

Probe Diameter

Phi 19 (Standard), Phi 16, Phi 12

Communication

Serial Output RS232/RS485/24VDC/600mA;220V AC/2W;

Power Supply

24V DC/600mA,220V AC/2W,110V AC/3W

Transport Package

Carton

Specification

80*30*30cm 6kg

Trademark

Aice Tech

Origin

China

HS Code

9026100000

Production Capacity

500000 Pieces/Year

Packaging & Delivery

Package Size

80.00cm * 30.00cm * 30.00cm

Package Gross Weight

6.000kg

Product Description

The thermal gas mass flow meter is designed based on the principle of thermal diffusion, which uses the constant temperature difference method to accurately measure the gas. The utility model has the advantages of small volume, high digitization degree, convenient installation and accurate measurement.

The sensor part consists of two reference grade platinum resistance temperature sensors. When the instrument is working, one sensor continuously measures the medium temperature T1; the other sensor self-heats to the medium temperature T2, which is used to sense the fluid flow rate, called the speed. sensor. The temperature Δ T=T2-T1, T2>T1, when there is fluid flowing, the gas molecules collide with the sensor and take away the heat of T2, so that the temperature of T2 is lowered. To keep ΔT unchanged, it is necessary to increase T2. The supply current, the faster the gas flow rate, the more heat is removed, and the gas flow rate and the added heat have a fixed function relationship. This is the principle of constant temperature difference.

compensation for gas flow measurement, and the measurement is convenient and accurate. A mass flow rate of the gas or a standard volume flow can be obtained.

for gas leak detection.

The sensor part consists of two reference grade platinum resistance temperature sensors. When the instrument is working, one sensor continuously measures the medium temperature T1; the other sensor self-heats to the medium temperature T2, which is used to sense the fluid flow rate, called the speed. sensor. The temperature Δ T=T2-T1, T2>T1, when there is fluid flowing, the gas molecules collide with the sensor and take away the heat of T2, so that the temperature of T2 is lowered. To keep ΔT unchanged, it is necessary to increase T2. The supply current, the faster the gas flow rate, the more heat is removed, and the gas flow rate and the added heat have a fixed function relationship. This is the principle of constant temperature difference.

Features:

-

- Thermal gas mass flow meters have the following technical advantages:

-

- The real mass flow meter does not require temperature and pressure

compensation for gas flow measurement, and the measurement is convenient and accurate. A mass flow rate of the gas or a standard volume flow can be obtained.

-

- Wide range ratio, can measure gas flow rate up to 120Nm / s down to 0.1Nm/ s, can be used

for gas leak detection.

-

- The seismic performance is good and the service life is long. The sensor has no moving parts and pressure sensing parts and is immune to the influence of vibration on the measurement accuracy.

- Easy to install and maintain. Non-stop production installation and maintenance can be achieved where field conditions permit. (requires special customization)

- Digital design. The overall digital circuit measurement, accurate measurement and convenient maintenance.

-

- RS-485 communication enables factory automation and integration.

-

- Oxygen, nitrogen, hydrogen, chlorine and multi-component gas measurements.

-

- blast furnace gas, coke oven gas measurement.

-

- Gas flow measurement of natural gas, liquefied gas, flare gas, etc.

-

- Primary and secondary air flow measurements of blast furnaces in the power plant.

-

- Flow measurement of down hole ventilation or exhaust system in Yanzhou Mine.

-

- Flue gas measurement.

-

- Compressed air measurement.

Technical performance

| performance | Technical Parameters | |

| structure type | Insertion | Pipeline |

| Measuring medium | Common steady-state gases (unstable media such as acetylene and boron trichloride are not measurable) | |

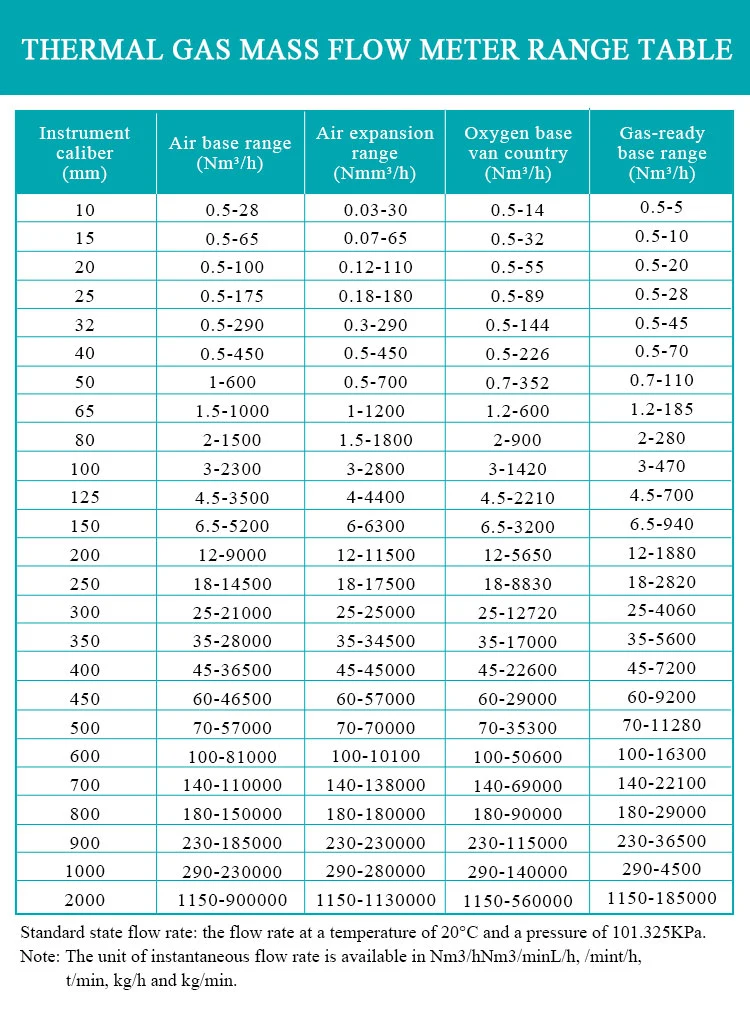

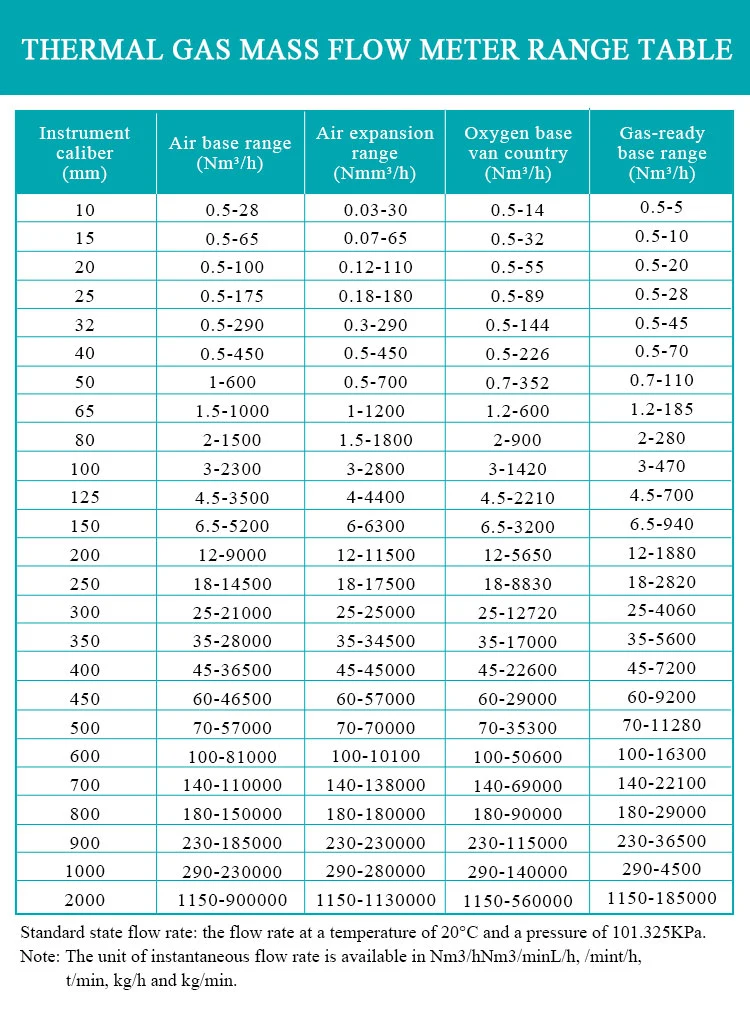

| Pipe diameter range | DN65~4000mm | DN15~2000mm |

| Flow rate range | 0.1~120Nm/s | |

| Accuracy | ±1~2.5% | |

| Operating temperature | sensor:-40~+450ºC converter:-20~+45ºC | |

| Working pressure | Medium pressure≤4.0MPa(≥4.0MPa Agreement supply) | Medium pressure≤1.6MPa(≥4.0MPa Agreement supply) |

| Power supply | (DC 24V )>=18W | |

| Responding speed | 1s | |

| Output signal | 4-20mA(Optical isolation,Maximum load500ohm),RS-485 (Lightning protection) | |

| Call the set | 1-2 normally open contacts,24V/0.5A | |

| Type of supply | Integrated structure | |

| Pipe material | Carbon steel, stainless steel, plastic, etc. | |

| Live display | Four-line LCD display | |

Display content | Mass flow rate, standard volume flow rate, cumulative flow rate, standard flow rate, etc. | |

| Protection level | IP65,IP67,IP68 | |

| Sensor material | stainless steel | Stainless steel, carbon steel |